NO ARMOR IS BULLET PROOF! Different armor models are meant to protect against specific types of ammunition. No body armor will stop every threat. Units should select armor designed to protect against the threats most likely to be faced by their team. At a minimum, armor should be selected that will protect against handguns threats.

Alternatives would include plate carriers with hard armor plates in lieu of complete wrap-around soft armor protection to provide rifle protection to vital anatomical areas.

Soft Armor

Soft body armor consists of flexible panels of ballistic material. Soft armor is designed to offer protection against assaults with handguns. It is intended to be used for extended daily wear. It is the type of body armor that officers

would typically wear while executing their daily duties. It can be worn under a uniform or other clothing in an external carrier. If it is worn under a uniform, it is called concealable armor.

Soft armor panels are constructed of multiple layers of ballistic-resistant materials. The number and order of layers influence overall performance. Additional energy is absorbed by each successive layer of material. When a handgun bullet strikes the panel, it is caught in a web of strong fibers. These fibers absorb and disperse the impact energy, causing the round to deform or “mushroom.“ While soft armor is most often seen in the form of panels for carriers or concealment vests, it can be cut to practically any shape, for multiple uses, keeping the layers and sew pattern the same to maintain protection integrity.

Hard Armor

Hard armor consists of rigid panels, or plates, of ballistic-resistant material and is

designed to offer greater protection against higher threats than soft armor. Hard armor plates are used in tactical armor. Tactical armor is not typically worn for extended periods. It is donned for wear by First Responders entering high-risk situations.

Hard armor plates may be constructed from ceramic, compressed laminate sheets,metallic plates, or composites that incorporate more than one material. Basically, hard armor plates work in one of two ways: they can capture and deform the ammunition round or they can break it up. In both instances, the armor then absorbs and distributes the force of the impact.

What is it and why does NIJ Certification matter?

The National Institute of Justice is the government agency responsible for establishing certification and protection standards for body armor. The armor sold by MED-TAC International Corp. undergoes routine testing at an NIJ approved laboratory, allowing us to guarantee its protection against specific threats.

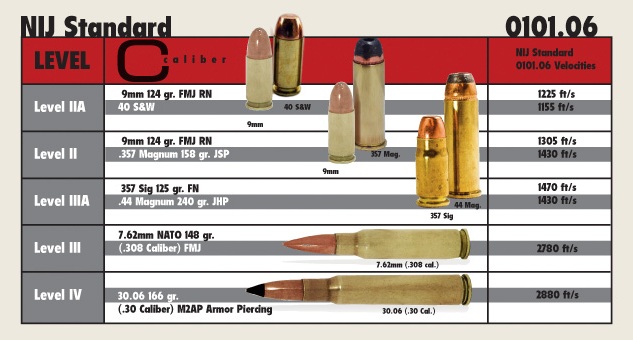

Level IIA

Tested to stop 9mm and .40 S&W ammunition fired from short barrel handguns. No rifle ammunition protection.

Level II

Tested to stop 9mm and .357 Magnum ammunition fired from short barrel handguns. No rifle ammunition protection.

Level IIIA

Tested to stop.357 SIG and .44 Magnum ammunition fired from longer barrel handguns. No rifle ammunition protection.

Level III

Tested to stop 7.62 mm FMJ (full metal jacket) lead core rifle ammunition.

Level IV

Tested to stop.30 cal steel core armor piercing rifle ammunition.

Special considerations

5.56mm ammunition comes in a variety of constructions. The rounds with lead cores typically used for hunting and target shooting can be stopped with Level III hard armor plates.

5.56mm ammunition (M855), designed for military use with a steel or partial steel core, needs a ceramic or metallic component to the hard armor plate and may be stopped by Level IV plates or those with an NJI III+ or Special Threat Designation.

V50 is a critical measure in assessing the ballistic performance of helmets. Let’s dive into the details:

What is V50?

- The V50 test involves firing specific projectiles at the helmet to determine the velocity at which they penetrate.

- The tests are conducted with varying levels of kinetic energy to simulate common battlefield scenarios.

- The goal is to understand where the helmet will fail and how it performs against ballistic threats.

- The National Institute of Justice (NIJ) sets standards for protective equipment.

- Helmets undergo V50 testing to ensure they can withstand ballistic threats.

- The V50 standards include a series of four ballistic tests using different rounds with varying energy levels.

- For example, the initial test involves a 17-grain bullet fired from a 22” .223 barrel.

- While NIJ Level IIIA helmets cannot fully stop penetration from high-velocity projectiles, they are crucial in mitigating injuries caused by fragmentation near blast zones.

Why V50 Matters:

Most battlefield head injuries result from fragmentation due to proximity to blast radius.- Helmets must be able to withstand these fragments.

- V50 testing helps manufacturers ensure their products meet safety standards and protect those who rely on them.

- Remember, V50 testing ensures that helmets can withstand ballistic threats and keep our protectors safe.

The higher the V50 number, the greater protection it provides.

My Wishlist

Wishlist is empty.